Portal for more climate-friendly mobility

More sustainable liquefied biogas

Using wind power to produce green hydrogen and even liquefied biogas via electrolysis: it really does work! A Danish-Norwegian company shows how it’s done.

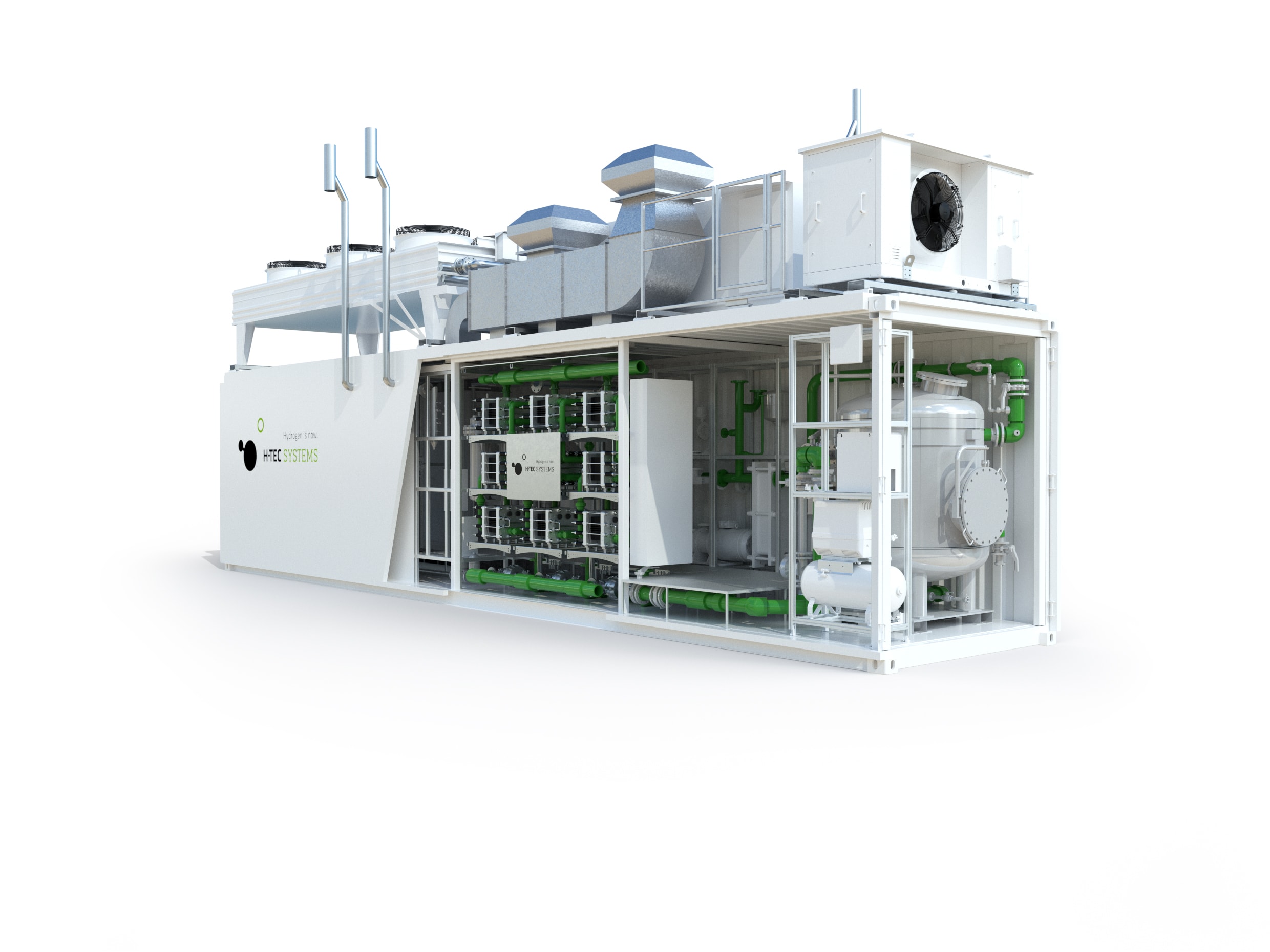

With such a compact PEM electrolyser from the German manufacturer H-Tec, around 450 kg of hydrogen can be produced per day. Source: H-Tec Systems.

With such a compact PEM electrolyser from the German manufacturer H-Tec, around 450 kg of hydrogen can be produced per day. Source: H-Tec Systems.

The Danish company GrønGas currently operates two biogas plants in the northern part of Jutland. For the first time anywhere in the world, this innovative company is now looking to use a technology that makes direct use of green hydrogen for the production of liquid biogas (LGB). Norwegian Hydrogen and the Danish energy entrepreneur, Jens Peter Lunden, have set up a 50:50% joint venture under the name Grøn Brint. “We want to be a pioneer in the use of green hydrogen for a variety of purposes,” says Jens Berge, CEO of Norwegian Hydrogen. “This collaboration shows that we can meet some of the huge demand for LBG by using green hydrogen and green CO2 in a new and innovative way.”

View of the GrønGas plant in Hjørring, Denmark, from above with the wind turbines in the background, which are to supply the green electricity for hydrogen production. Source: GrønGas

View of the GrønGas plant in Hjørring, Denmark, from above with the wind turbines in the background, which are to supply the green electricity for hydrogen production. Source: GrønGas

Green hydrogen is used for the production of LBG/bio-LNG, which means that the CO2 is “green” as well. The conversion of CO2 into synthetic gas offers added value for all parties and also forms the basis for profitability. “We’ve all been working closely alongside each other to develop a model for this collaborative undertaking. Together, we intend to demonstrate an integrated, green and profitable value chain from wind turbines through to electrolysis and LBG,” explains Jens Peter Lunden proudly.

Allan Olesen, CEO of GrønGas, is also looking forward to collaborating on producing bio-LNG/LBG in an even more sustainable way. The sustainability of production is greatly improved by Carbon Capture and Utilization (CCU), i.e. the capture, transport and use of CO2. “In the near future, we hope to be able to use hydrogen for CCU and methanation directly at the biogas plant,” says Allan Olesen. “Our aim is to join the same sustainable value chain that Grøn Brint is part of.”

With bio-LNG in the tank, a ship, a truck or even this Iveco Pace Truck with LNG propulsion, which is used in European Truck Racing Championship, is almost CO2-neutral on the road. Source: CNG-Mobility.ch

With bio-LNG in the tank, a ship, a truck or even this Iveco Pace Truck with LNG propulsion, which is used in European Truck Racing Championship, is almost CO2-neutral on the road. Source: CNG-Mobility.ch

The electrolysers to be used for the production of green hydrogen are soon to be supplied by the German manufacturer H-Tec Systems. This means that before the end of 2023, it will be possible to start production of bio-LNGs, which are in demand throughout Europe for a variety of applications, be it in transport for trucks with LNG engines or ships with LNG engines or for industrial use. “The Grøn Brint joint venture offers an innovative approach to hydrogen production which we are happy to serve with our modular electrolysers,” explains Robin v. Plettenberg. The CEO of H-Tec Systems adds: “Initiatives like this can serve as a model for similar projects in a lot of other European countries. More and more practical applications are showing how green hydrogen can help meet net-zero emissions targets and accelerate the energy transition.”

The parties intend to extend their cooperation to include further possibilities for the production of hydrogen and other e-fuels using wind energy, with further major projects already in the pipeline, so we can look forward not just to the first LBG from Jutland, but also to other ideas from the Vikings. (pd/jas, 30 March 2023)

Using wind power to produce green hydrogen via electrolysis – as in the picture with this system from H-Tec-Systems – has been possible for a long time, but now Grøn Brint is also producing liquefied biogas in an even more sustainable way. Source: H-Tec-Systems

Using wind power to produce green hydrogen via electrolysis – as in the picture with this system from H-Tec-Systems – has been possible for a long time, but now Grøn Brint is also producing liquefied biogas in an even more sustainable way. Source: H-Tec-Systems

You might also be interested in

Shell Starship on record hunt