Portal for more climate-friendly mobility

Actively reduce CO2 in biogas production

The biogas plant in Reimlingen, Bavaria, will soon not only produce biogas, but will even also actively extract CO2 from the atmosphere. This clever project is made possible by a joint venture between Landwärme and Reverion. The two companies have now even received the Innovation Award of the German Gas Industry.

Biogas plant in Reimlingen (D), Bavaria, which will soon not only produce biogas for but also extract CO2. Source: Landwärme

Biogas plant in Reimlingen (D), Bavaria, which will soon not only produce biogas for but also extract CO2. Source: Landwärme

Decarbonisation in road and freight transport is hugely important. Passenger cars and trucks with a CNG or LNG engine and biogas in the tank also play an important role in this regard. However, in order to achieve the net zero targets set by policymakers, the calls for projects that make it possible to even extract and store CO2 from the atmosphere or to continue using the CO2 – so-called CCS (Carbon Capture and Storage) or CCU (Carbon Capture and Usage) – are also growing louder.

The Landwärme team makes it possible: The biogas plant in Reimlingen (D), Bavaria, actively extracts CO2 from the atmosphere as part of its biomethane production process. Source: Landwärme

The Landwärme team makes it possible: The biogas plant in Reimlingen (D), Bavaria, actively extracts CO2 from the atmosphere as part of its biomethane production process. Source: Landwärme

“The clock is ticking. Not only do we have to reduce emissions as quickly as possible, but we also have to remove the excessive amount of CO2 in the air from the atmosphere,” explains Zoltan Elek, Chief Executive Officer of Landwärme. “The CO2 content in the atmosphere is around 0.04%. Filtering out CO2 using direct air capture methods, for example, is a very complex process. This is much more effective and easier when it comes to capturing CO2 during the conversion of biogas into biomethane.”

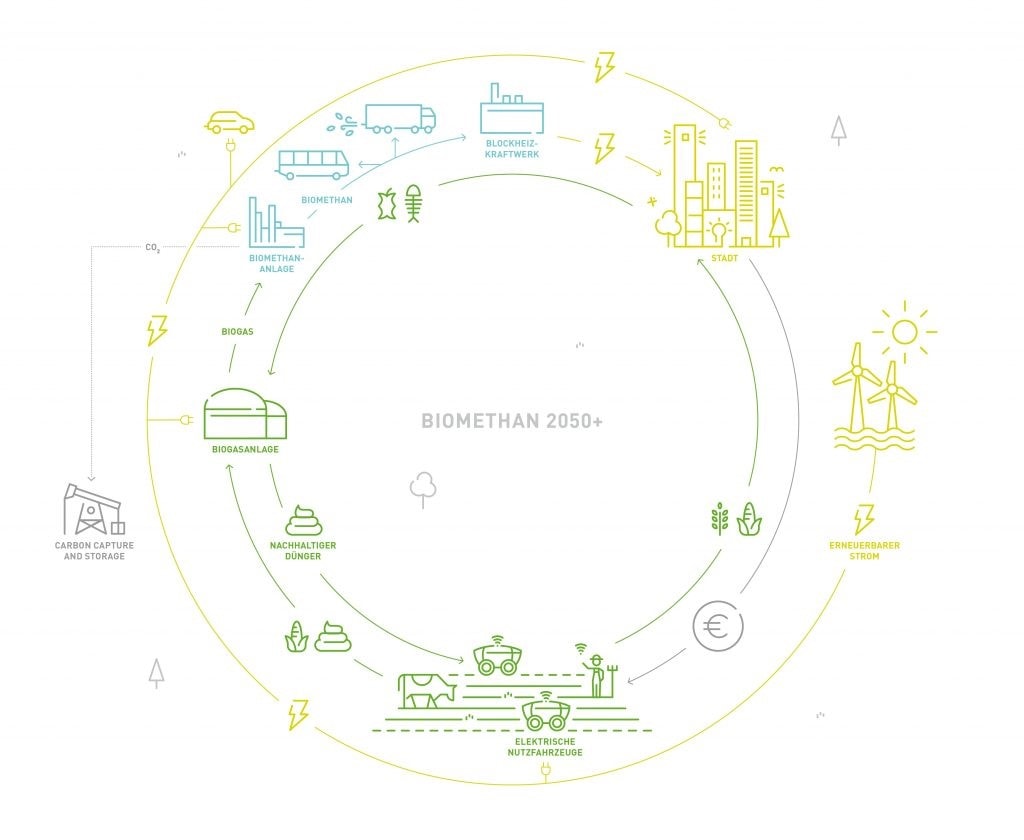

Source: Zukunft Gas

His German biomethane trading and service company Landwärme GmbH and Reverion GmbH, a spin-off of the Technical University of Munich, use a basic principle which couldn’t be easier. After all, CO2 capture is already part of the production process when converting (i.e. purifying) biogas into biomethane. Incidentally, this part of the procedure is already being used successfully in Switzerland at Ara Region Bern AG. Here, the captured and already very pure CO2 is used by Neustark for the carbonation of concrete granules.

At the biogas plant in Reimlingen, Germany, where an annual capture of around 10,000 tonnes of CO2 is planned, gas processing is still combined with electricity generation. At the heart of the process is a combination of high-temperature solid oxide fuel cells with catalytic methanation. Part of the biogas is converted into electricity in a highly efficient manner using a fuel cell, recirculating the CO2 produced and capturing it during the existing gas treatment process – a novelty.

Landwärme and Reverion won the Innovation Award of the German Gas Industry in the “Sustainable Generation” category with their joint CCS project. Source: Zukunft Gas / Claudius Pflug

Landwärme and Reverion won the Innovation Award of the German Gas Industry in the “Sustainable Generation” category with their joint CCS project. Source: Zukunft Gas / Claudius Pflug

The clever system can also use surplus electricity in the grid and generate hydrogen by means of electrolysis. “Our technology will enable us to generate CO2-negative electricity for the first time,” explains Stephan Herrmann, founder and managing director of Reverion. “In times of high solar and wind power generation, we can produce gases that can be stored over the long term, thereby reducing our dependence on imports from third countries.” Incidentally, the CO2 captured will be liquefied in the next step, like in Bern. For example, it can be stored in deep layers of stone or alternatively used as carbon dioxide in technical applications such as fire extinguishers or in the food industry. (pd/jas, 27 October 2022)

Source: Landwärme

Source: Landwärme

Other award winners in 2022

For the 22nd time already, the three industry associations BDEW, DVGW and Zukunft Gas presented the Innovation Award of the German Gas Industry. Other prize winners were::

Wasserstoffdorf Bitterfeld and Mitteldeutsche Netzgesellschaft Gas GmbH: with its test infrastructure in the hydrogen village of Bitterfeld, Mitnetz Gas and its partners create diverse, important and practical empirical values in the transport, distribution and use of 100% hydrogen.

PSIcontrol, Greengas and PSI Software AG: in the future, there will be different gases with different properties in the existing gas infrastructure. With the “Green Gases Grid Simulation,” PSI has created a preview solution for the climate-neutral and flexible operation of gas networks.

H2-Micro-Mix-Brenner, Kawasaki Gas Turbine Europe GmbH, B&B-AGEMA GmbH, Institut für Dampf- und Gasturbinen an der RWTH Aachen and FH Aachen: Kawasaki Gas Turbine Europe and scientific partners have realised operational gas turbine burners using hydrogen and up to 50% methane, which is an important contribution to CO2-free power supply and to making future energy supply more flexible.

You might also be interested in

Shell Starship on record hunt