Portal for more climate-friendly mobility

Wastewater becomes renewable energy

Ara Region Bern AG (Arabern) is no longer just concerned with wastewater treatment; it has also become a successful producer of renewable energy. In this interview, Adrian Schuler, Managing Director of Arabern, reveals the details and explains current energy supply challenges.

The Arabern is not only one of the largest wastewater treatment plants in Switzerland, but also a regional energy hub. Source: Arabern

The Arabern is not only one of the largest wastewater treatment plants in Switzerland, but also a regional energy hub. Source: Arabern

Arabern is located right next to the Neubrügg, the covered, 16th century wooden bridge, in a picturesque loop of the Aare river. It is one of the largest wastewater treatment plants in Switzerland. It began operations in 1967 and has been continuously developed and expanded – with the addition of the first biogas plant in 2008, for instance. Today, it is one of the most important biogas producers in the region. The company and its 32 employees are responsible for the comprehensive use of biomass in addition to its core business, wastewater treatment. This allows Arabern to utilise synergies at a local level, ensuring sustainable sanitation and protecting the environment.

Ara Region Bern AG has become a veritable energy hub. In addition to its core business of wastewater treatment, the company now also produces renewable energy. How did this happen?

Adrian Schuler, Managing Director of Arabern: The sewage sludge from the sewage treatment plant is fermented in digesters. Fermentation produces biogas – a mixture of methane, CO2 and other gaseous substances. Fermentation is nothing new. It is a process that has been taken from nature and is used in many sewage treatment plants. The biogas can be used directly as an energy carrier or is released into the gas grid when processed into biomethane. During this process the unwanted gases such as CO2 are separated from the methane.

Adrian Schuler, managing director of Arabern, explains details of biomass processing to visitors. Source: CNG-Mobility.ch

Adrian Schuler, managing director of Arabern, explains details of biomass processing to visitors. Source: CNG-Mobility.ch

You run a collection point for biogenic waste, how much biomass does Arabern process every day?

Around 200 tonnes are processed every day.

What exactly happens to it?

The origin of the biomass varies greatly, as does its processing. The main job of the new plant, which has been in operation since 2020, is to unpack foods that can no longer be eaten. Liquid biogenic waste such as grease trap sludge from commercial kitchens is also accepted.

The modern plant is also able to cleanly separate packaging materials from the biogenic residues, thus creating good conditions for further processing in the digestion towers. Source: CNG-Mobility.ch

The modern plant is also able to cleanly separate packaging materials from the biogenic residues, thus creating good conditions for further processing in the digestion towers. Source: CNG-Mobility.ch

Do you have to carefully sort the organic waste that is delivered, or what happens, for example, to plastic and other contaminants that end up in green bins?

The new plant technology does a great job of cleanly separating the packaging from the organic components. The sorted packaging is transported to the nearby waste incineration plant where it is used to generate thermal energy. By the way, the contents of domestic green bins are not sent to Arabern. This material is better suited for composting than fermentation. Therefore, it is mainly the collection containers of catering companies that bring their scraps and leftovers to us for fermentation. However, these contents usually contain very few contaminants anyway. The returns from major distributors are unpacked. Anything that is no longer edible must be disposed of. Unpacking all of this by hand would hardly be feasible. Fortunately, our systems do this very reliably.

How is biomass turned into sustainable energy and what should be paid particular attention during this process?

The treated biomass and the sewage sludge from the wastewater treatment system are fed into the digesters. The entire mass is fermented at a consistent 38°C for around twenty days. Microorganisms convert the carbon-rich food into methane gas and CO2 (biogas).

One of the 32 employees checks the hammer mill to see if any foreign material could hinder the correct further processing of the biomass. Source: CNG-Mobility.ch

One of the 32 employees checks the hammer mill to see if any foreign material could hinder the correct further processing of the biomass. Source: CNG-Mobility.ch

How much biogas can Arabern produce and what happens to it?

Around eight million cubic metres. Processed into biomethane, this corresponds to around 50 gigawatt hours of energy. This gas would be able to fuel around 7,000 vehicles driving 15,000 kilometres a year.

Can this be scaled up further and can it contribute to energy security, which is currently being critically examined?

The volume can be increased within the plant’s technical limits. However, you can’t just “feed” any old biogenic material into the fermentation systems of a wastewater treatment plant. Woody components, such as food containers made from palm leaves, cannot be fermented. Good substrates, i.e. high-energy, easily digestible waste, are not available in large quantities, and after all, we need most of the digester’s volume to ferment the sewage sludge.

The Arabern’s impressive plant is capable of processing around 200 tonnes of biomass a day. Source: CNG-Mobility.ch

The Arabern’s impressive plant is capable of processing around 200 tonnes of biomass a day. Source: CNG-Mobility.ch

Around a third of the CO2 is extracted from biogas before it is fed into the gas grid as biomethane. What does Arabern do with it?

The already very pure CO2 is taken by Neustark. Neustark’s goal is to extract CO2 from the atmosphere forever. A very successful approach to this is the carbonation of concrete granules. During carbonation, CO2 is converted into calcium carbonate, i.e. limestone, and thus becomes permanently stored in the rock, keeping it out of the atmosphere.

What are the advantages of this process and how has the cooperation with the start-up Neustark developed?

The process – i.e. the conversion to limestone – is quite quick and does not require any additional energy. The new concrete produced with this concrete granulate also requires less cement to achieve the same strength. The reduced consumption of cement therefore has a further positive effect on the concrete’s ecological footprint.

Here, another load of CO2 is being filled for the start-up “Neustark”, which will then be transported to its destination in a biogas truck from Salzmann AG Transporte in an almost CO2-neutral manner. Source: CNG-Mobility.ch

Here, another load of CO2 is being filled for the start-up “Neustark”, which will then be transported to its destination in a biogas truck from Salzmann AG Transporte in an almost CO2-neutral manner. Source: CNG-Mobility.ch

If regional biogas production works so well in Bern, why isn’t the process much more commonplace? Are the conditions elsewhere too complex?

The process is already well established in many wastewater treatment plants, and not only in Switzerland. Many plants need their own biogas to produce electricity and heat for their own needs. For Arabern, processing and feeding in biomethane proved to be the better option, as heat energy can be obtained as waste heat from the nearby Forsthaus WIP. Both options have advantages and disadvantages.

Adrian Schuler, managing director of Arabern, has developed his company into a hub for renewable energy. Source: CNG-Mobility.ch

Adrian Schuler, managing director of Arabern, has developed his company into a hub for renewable energy. Source: CNG-Mobility.ch

Are there any plans for expansion in Bern or what are the next steps towards a “net zero” strategy?

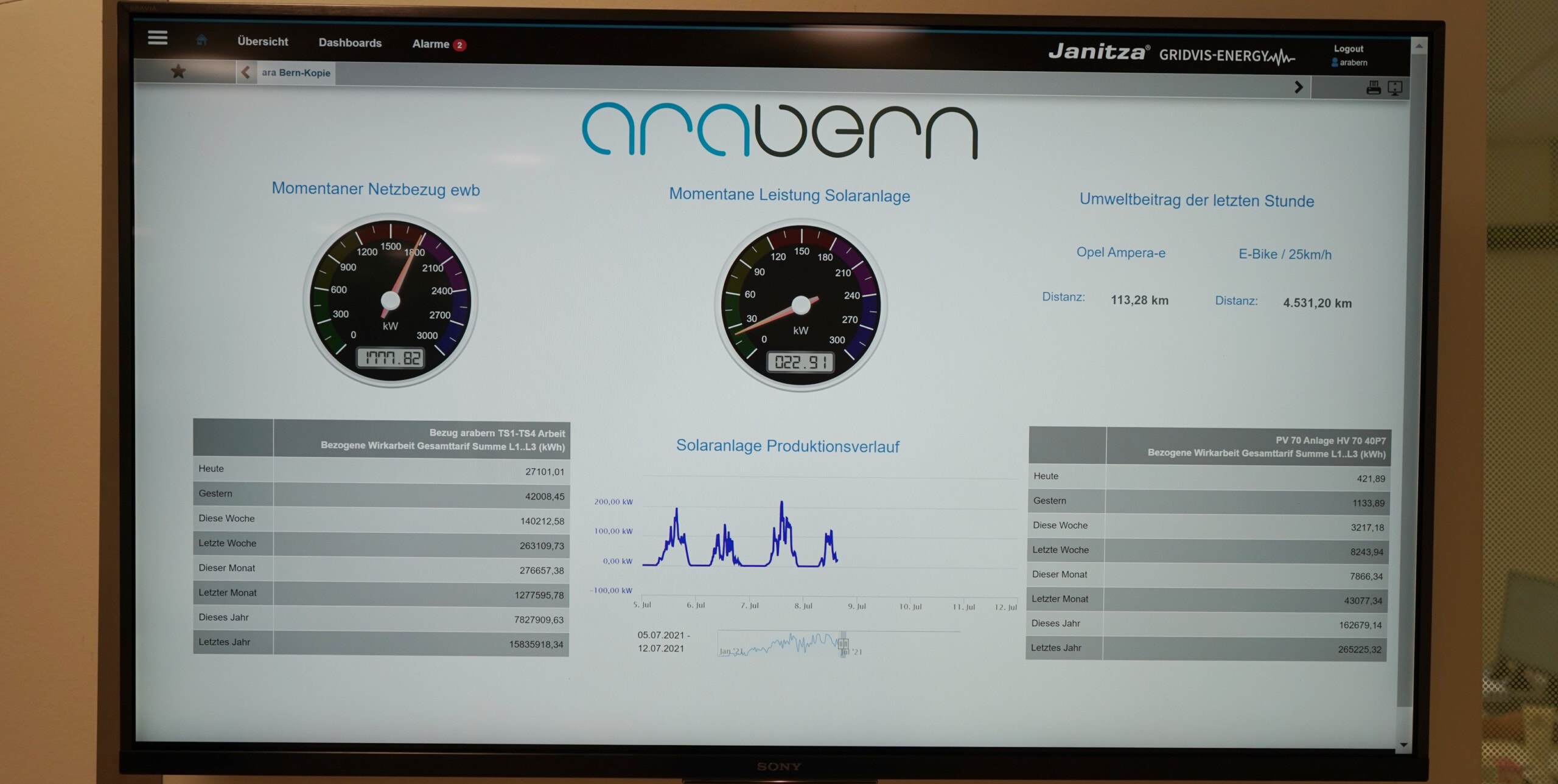

Over the past few years, we have continuously optimised our existing plants and optimised them for efficiency. Cleaning wastewater inevitably requires energy. In the future, requirements with regard to the quality of the purified wastewater will become more stringent. New cleaning stages require yet more energy. We already give a great deal of thought to energy efficiency during the planning stage. Ultimately, however, there is always a great need for energy. Here, we focus consistently on purchasing energy that is as environmentally friendly as possible, such as Swiss hydroelectric power, and on using waste heat. We equip our buildings with photovoltaic systems wherever technically feasible. The solar power produced on the site could already cover the needs of around 70 detached homes – but unfortunately this is only a fraction of what we need. (jas, 27 September 2022)

Arabern not only supplies clean water and biogas, but also green electricity thanks to a photovoltaic system. Source: CNG-Mobility.ch

Arabern not only supplies clean water and biogas, but also green electricity thanks to a photovoltaic system. Source: CNG-Mobility.ch

You might also be interested in

Shell Starship on record hunt