Portal for more climate-friendly mobility

3.4 kilotonnes of bio-LNG for the island

The demand for renewable fuel in heavy goods transport is growing throughout Europe. That is why the first bio-LNG/LBG plant is now also being built in the UK. The project by RenEco and Nordsol is expected to supply 3.4 kilotonnes of bio-LNG/LBG annually from the first quarter of 2024.

One of the 40,000 or so LNG-powered vehicles in Europe pulls up at the Shell filling station in Azuqueca de Henares in Spain. Source: Shell

One of the 40,000 or so LNG-powered vehicles in Europe pulls up at the Shell filling station in Azuqueca de Henares in Spain. Source: Shell

According to the European industry association NGVA Europe, there are already almost 700 LNG refuelling stations in Europe, and the number is steadily increasing. The energy giant Shell, for example, has just opened LNG refuelling stations in France directly on the A40 motorway in Haute-Savoie, halfway between Geneva and the Mont Blanc Tunnel, and in Austria near St. Marienkirchen close to the German border. This helps massively in the decarbonisation of heavy goods traffic, because even if a truck is already running on fossil LNG instead of diesel, this makes a CO2 reduction of 15 to 20 percent possible.

German retailer Edeka was part of a pilot by Shell Germany for trucks with LNG propulsion and bio-LNG/LBG in the tank in 2021. Source: Iveco/Christian Schwier/Jonathan Fafengut

German retailer Edeka was part of a pilot by Shell Germany for trucks with LNG propulsion and bio-LNG/LBG in the tank in 2021. Source: Iveco/Christian Schwier/Jonathan Fafengut

If the trucks instead run on cryogenic and therefore liquefied LNG from sustainable sources, they can even transport their goods in an almost CO2-neutral way. Technically, moreover, no conversions or special adaptations are required on the truck for the use of LBG/bio-LNG. And the same maintenance intervals also apply, as a pilot test by the German retailer Edeka has already shown. Around 40,000 LNG-powered vehicles are already on the road in Europe. And truck manufacturer Iveco and energy giant Shell are even launching a special bio-LNG tour “On the Road to Net-Zero Emissions”: a ten-day long-distance trip through Europe with an Iveco S-Way LNG tractor unit to demonstrate the fuel’s suitability for everyday use.

Already since 2009, energy provider Rolande has been investing in LNG and now also bio-LNG/LBG infrastructure to decarbonise heavy transport. Source: Rolande

Already since 2009, energy provider Rolande has been investing in LNG and now also bio-LNG/LBG infrastructure to decarbonise heavy transport. Source: Rolande

“bio-LNG/LBG is a completely fossil-free and recyclable product. It saves up to 100 percent CO2 emissions compared to diesel,” also confirms Jolon van der Schuit, CEO of energy provider Rolande. “By enabling driving with bio-LNG/LBG on a larger scale, our customers and we are making an important contribution to the European Commission’s goal of climate-neutral operation in the transport sector by 2030.” This makes it all the more important that the growing LNG filling station network, which is incidentally also supported and promoted by the European Union as part of the BioLNG4EU project, gets enough bio-LNG/LBG and does not have to rely on fossil LNG.

Nordsol’s technology is not only convincing energy giants like Shell, but increasingly also private individuals, for example in the ROM Utrecht Region, who are investing in liquefaction plants. Source: Jos Hummelen, ROM Utrecht Region

Nordsol’s technology is not only convincing energy giants like Shell, but increasingly also private individuals, for example in the ROM Utrecht Region, who are investing in liquefaction plants. Source: Jos Hummelen, ROM Utrecht Region

Recently, the world’s largest biogas liquefaction plant to date has been producing the sustainable fuel for Biokraft in the south of Stockholm. The plant supplies renewable energy for 220 GWh per year and has a production capacity of 50 tonnes of bio-LNG/LBG per day. Now, UK-based RenEco and Dutch technology company Nordsol have announced that they will start up a first bio-LNG/LBG production plant in the UK in the first quarter of 2024.

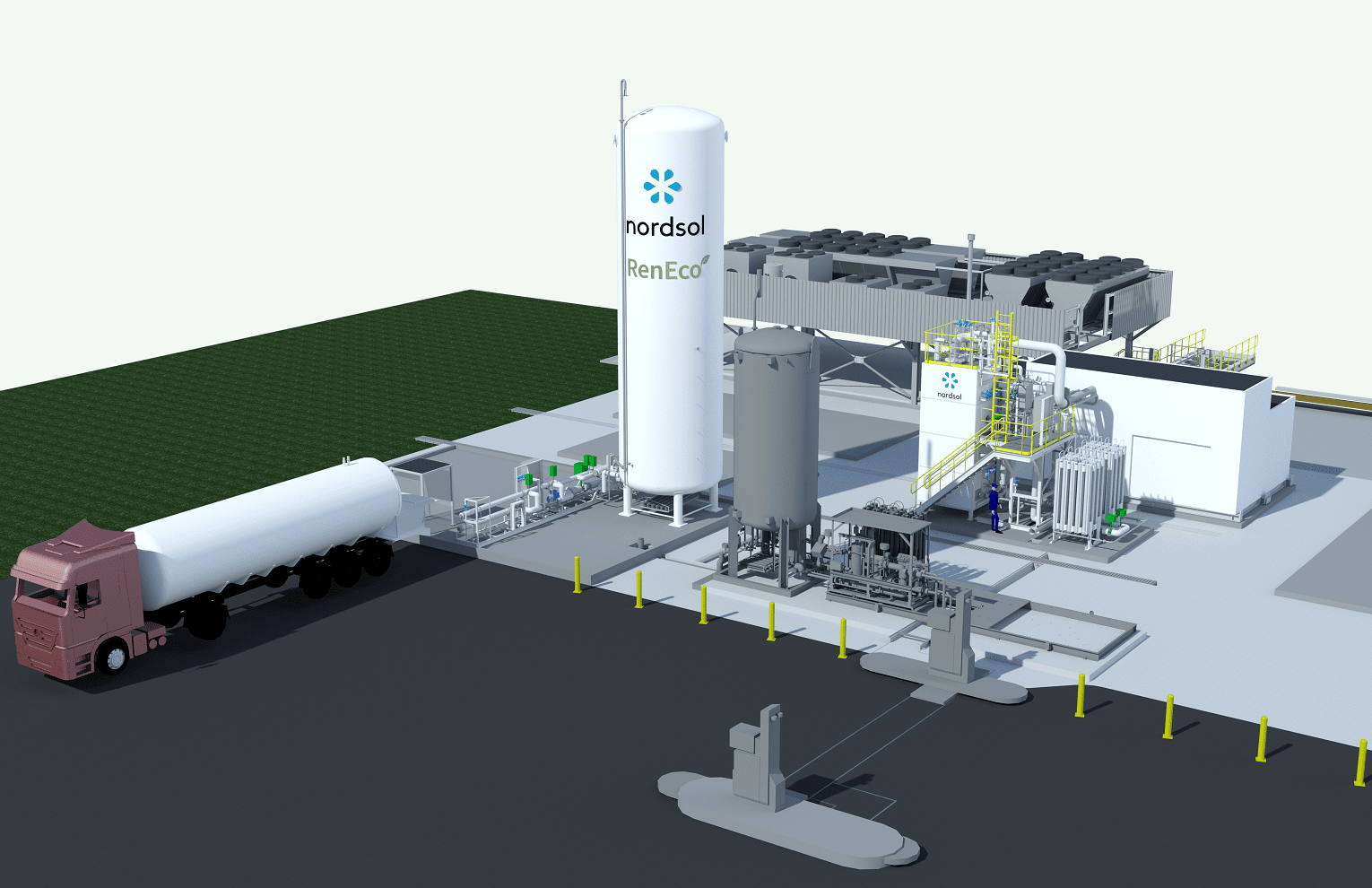

Sketch of the first liquefaction plant for bio-LNG/LBG in the UK. Source: Nordol

Sketch of the first liquefaction plant for bio-LNG/LBG in the UK. Source: Nordol

Located near Rushden two hours north of London, the plant currently processes organic waste into biogas and electricity. Now RenEco wants to use Nordsol’s technology to convert biogas into liquefied bio-LNG/LBG. The new liquefaction plant is expected to produce 3.4 kilotonnes of bio-LNG annually, enabling more than 13 million kilometres of fossil-free heavy transport. “bio-LNG/LBG is the best solution for decarbonising the long-haul transport sector, for which it is otherwise very difficult to reduce emissions,” said Léon van Bossum, CEO of Nordsol. “With this first production plant in the UK, we are demonstrating that on-site liquefaction of biogas is not only sustainable, but also affordable and scalable.”

The plant is an essential part of a rapidly developing circular economy. RenEco’s initiative involves collecting organic waste from the food supply, converting it into biogas and organic fertiliser through anaerobic digestion, and converting biogas into the renewable products bio-LNG/LBG and biogenic CO2. While biogenic CO2 is replacing fossil CO2 in various industries, RenEco’s fleet will soon be powered by sustainable bio-LNG/LBG along with customers’ fleets, closing further material loops and preventing emissions.

The British family-owned company Nicholls Transport also delivers goods with bio-LNG for the multinational plasterboard manufacturer Knauf, among others. Source: Knauf

The British family-owned company Nicholls Transport also delivers goods with bio-LNG for the multinational plasterboard manufacturer Knauf, among others. Source: Knauf

“Following extensive market research into how we can decarbonise both our own truck fleet and the fleets of our retail customers, Nordsol was selected as a long-term partner to provide sustainable fuel through liquefaction technology,” explained William Wykes, Director RenEco. “Phase one of the bio-liquefaction plant will produce enough bio-LNG/LBG to fuel 100 trucks operating 24 hours a day, seven days a week.” (jas, 28 September 2023)

You might also be interested in

Shell Starship on record hunt