Portal for more climate-friendly mobility

Full bio-power for heavy transport

The biofuel liquefaction plant in the south of Stockholm will soon be able to produce 50 tonnes of bio-LNG/LBG per day – which will benefit heavy goods traffic throughout Europe. Because this will provide it with the urgently needed quantities of renewable fuel for the transformation of the transport sector and the increasing demand for bio-LNG/LBG.

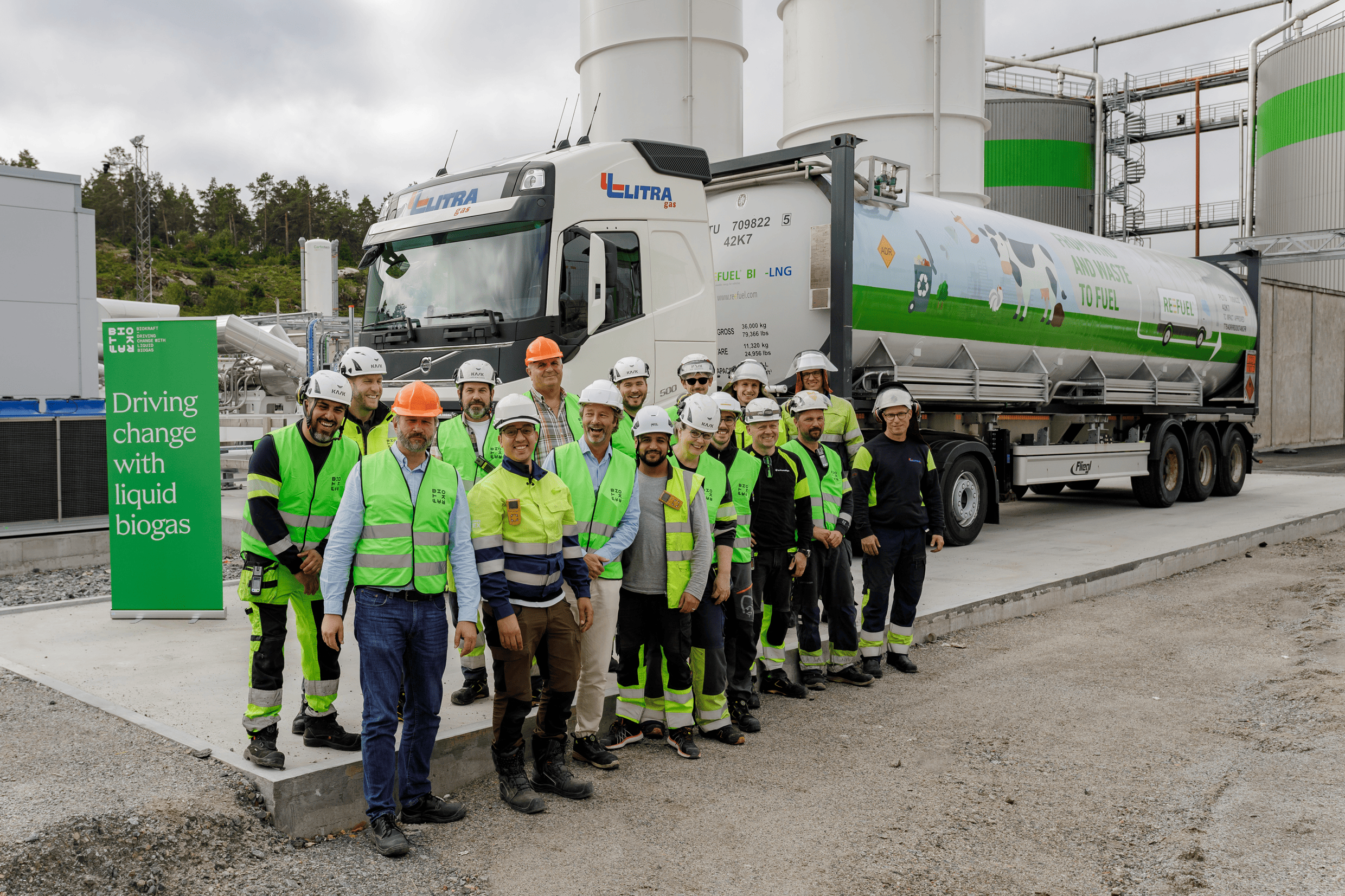

The first cargo of Bio-LNG/LBG leaves Biokraft’s new large-scale liquefaction plant in Sweden. Source: Biokraft

The first cargo of Bio-LNG/LBG leaves Biokraft’s new large-scale liquefaction plant in Sweden. Source: Biokraft

Throughout Europe, more and more LNG is being used in heavy-duty transport, which already enables a CO2 reduction of up to 20 percent compared to a diesel unit. The decisive factor, as with CNG drives, is the possibility of the so-called “fuel switch”. Instead of using fossil CNG or LNG, the entire vehicle can also be operated with biogas or liquefied biogas (LBG/Bio-LNG) without any problems and without additional technical adaptations, and is then almost CO2-neutral on the road.

The transport sector, but also other industries, could become more sustainable thanks to the use of bio-LNG/LBG and reduce their net carbon dioxide emissions by up to 95 percent compared to fossil fuels. Source: Biokraft

The transport sector, but also other industries, could become more sustainable thanks to the use of bio-LNG/LBG and reduce their net carbon dioxide emissions by up to 95 percent compared to fossil fuels. Source: Biokraft

Currently, “mixed refrigerant technology”, which is based on several different refrigerants, is predominantly used for the liquefaction of biogas. At the beginning of the year, a Swiss study by the Swiss Federal Office of Energy, Lidl Switzerland and the Research, Development and Promotion Fund of the Swiss Gas Industry (FOGA) showed that, on a well-to-wheel basis, replacing fossil diesel with LBG from Scandinavia can reduce the total CO2-relevant emissions of a truck from 1044 g to as low as 270 g CO2,eq /km. And now there is good news again from Scandinavia, where Biokraft, as Scandinavian Biogas, one of the leading biofuel producers with plants in Sweden, Norway and Korea, has been calling itself since this summer, has put a new bio-LNG project into operation.

The world’s largest biogas liquefaction plant to date doubles the Swedish company’s capacity to produce liquefied bio-LNG/LBG. The newly built liquefaction plant, which cost around CHF 38 million, is connected to the biogas plant in Södertörn near Stockholm. “The launch of Stockholm Bio-LNG is an important strategic milestone and strengthens our market position as one of the leading European Bio-LNG producers in the Northern European market,” explains Matti Vikkula, CEO of Biokraft. “The project also demonstrates that we have the competence and capacity to build and operate large biogas plants in line with our strategic growth plan.”

The first containers of cryogenic bio-LNG/LBG are filled for Biokraft’s customers in the south of Stockholm. Source: Biokraft

The first containers of cryogenic bio-LNG/LBG are filled for Biokraft’s customers in the south of Stockholm. Source: Biokraft

And Jean Collin, Senior Project Director at Biokraft, proudly adds, “It’s been exciting to manage this project, which despite all the challenges has been completed reasonably on schedule.” Now the plant has delivered its first batch of Bio-LNG/LBG. The delivery consisted of two containers and a total of 34 tonnes of Bio-LNG, which is primarily used by trucks in northern Europe. Thanks to this amount of LBG, even a fully loaded LNG-powered truck can travel around 100,000 kilometres in a climate-neutral manner. While Biokraft’s Stockholm Bio-LNG project will certainly be in the commissioning phase for a few more months while production is scaled and features and delivery parameters are tested. “We expect the plant to be ready for regular production towards the end of the year,” says Jean Collin confidently.

The German company Alternoil GmbH also benefits from part of the production of the large liquefaction plant. Source: Biokraft

The German company Alternoil GmbH also benefits from part of the production of the large liquefaction plant. Source: Biokraft

The plant has a production capacity of 220 GWh per year, making it currently the largest in the world with a production capacity of 50 tonnes of bio-LNG/LBG per day. Liquefaction significantly expands the company’s potential market to include heavy transport, shipping and industry. The liquefied bio-LNG/LBG, with its clearly higher energy content per unit volume than compressed biogas, can be produced at reasonable cost thanks to the large-scale plant and can also be easily transported over long distances. The German company Alternoil GmbH, for example, also benefits from this.

One of the filling stations for Reefuel in Germany, where trucks can fill up with LBG/Bio-LNG and then continue their journey in an almost CO2-neutral manner. Source: Alternoil/Reefuel

One of the filling stations for Reefuel in Germany, where trucks can fill up with LBG/Bio-LNG and then continue their journey in an almost CO2-neutral manner. Source: Alternoil/Reefuel

“The transformation of the transport sector and the increasing demand for bio-LNG and eLNG in heavy-duty transport require not only a continuous increase in our renewable fuel volumes and the expansion of our filling station infrastructure, but also reliable and long-term partnerships along the entire value chain,” explains Alexander Renz, Managing Director of Alternoil GmbH. In June, he had therefore already negotiated an exclusive purchase of the entire annual production volume of bio-LNG with the Danish biogas producer GrønGas A/S. In order to supply his steadily growing network of filling stations with LBG/bio-LNG, he now also receives renewable fuel from Biokraft to decarbonise heavy transport. From Södertörn alone, Alternoil is expected to source up to 6000 tonnes of bio-LNG/LBG annually in the future.

Thanks to its own bio-LNG filling station on the premises of the Edeka logistics centre in Lauenau (D) from Alternoil GmbH, the LNG Iveco are almost CO2-neutral on the road. Source: Iveco/Christian Schwier/Jonathan Fafengut

Thanks to its own bio-LNG filling station on the premises of the Edeka logistics centre in Lauenau (D) from Alternoil GmbH, the LNG Iveco are almost CO2-neutral on the road. Source: Iveco/Christian Schwier/Jonathan Fafengut

“The cooperation with Alternoil is an important strategic step for us,” says Biokraft CEO Matti Vikkula. “In order to jointly contribute to and drive forward the defossilisation of heavy-duty transport, we plan to increase our production capacity by another 2.5 TWh by 2030 and continue our search for land and projects in Germany and in Northern Europe to do so.” (pd/jas, 19 September 2023)

You might also be interested in

Shell Starship on record hunt