Portal for more climate-friendly mobility

Planned expansion of range

Sergio Giordana, Chief Engineer at FPT Industrial, talks about the challenges of developing CNG engines and their possible applications.

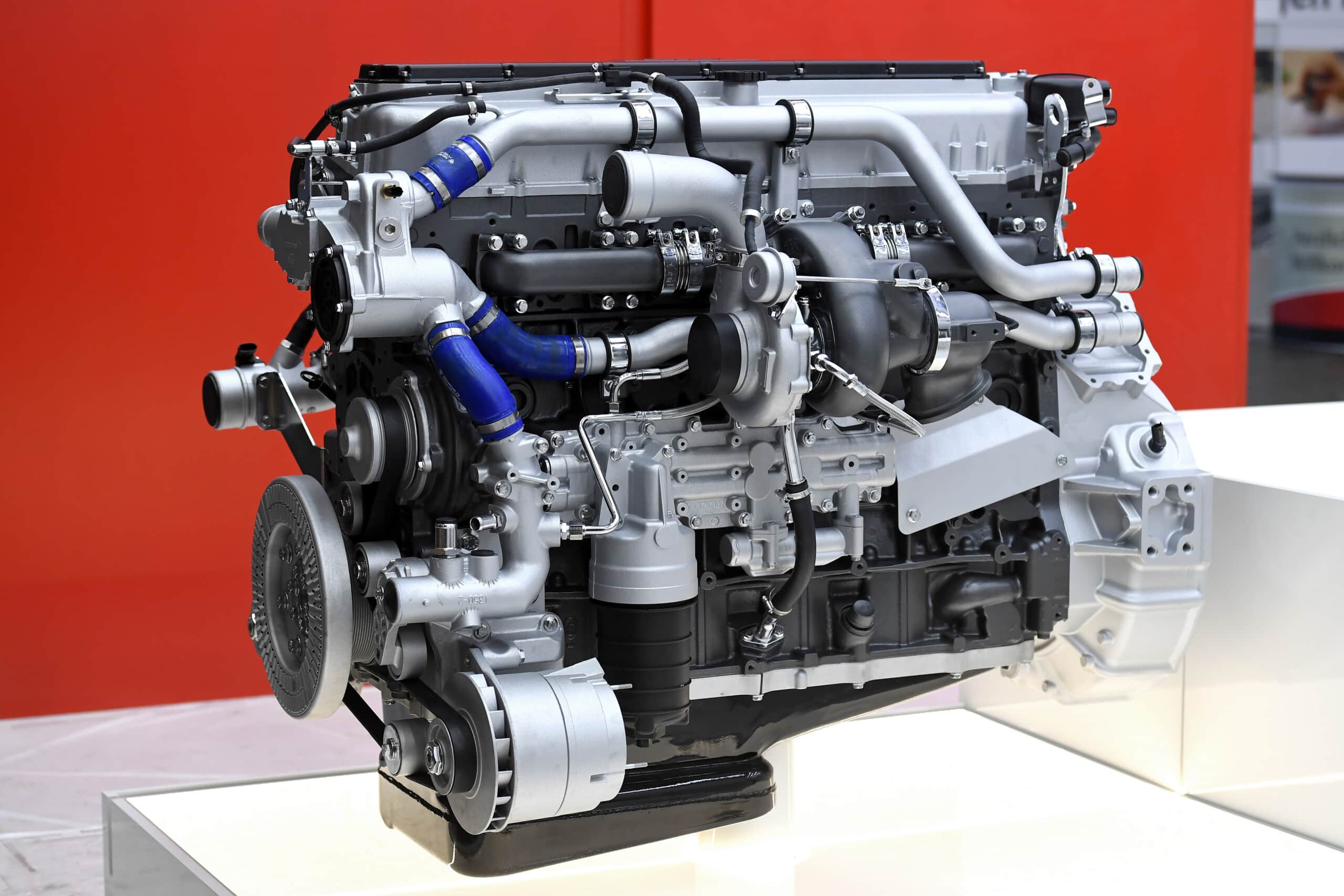

Five years ago, the Cursor 13 NG engine with 460 hp was unveiled for the first time during the “FPT Tech Day”. Source: FPT Industrial/Filippo Alfero

Five years ago, the Cursor 13 NG engine with 460 hp was unveiled for the first time during the “FPT Tech Day”. Source: FPT Industrial/Filippo Alfero

Strong performance, state-of-the-art technology, genuine sustainability – these are the hallmarks of CNG powertrains from specialist FPT Industrial. The company is part of CNH Industrial and is responsible for the development, production and sale of engine systems for on-road and off-road vehicles, ship and power generation applications. More than 55,000 gas engines sold all over the world over the past 25 years underline the great expertise of FPT Industrial.

Just like the Cursor 13 NG engine with 460 hp at 1,900 rpm and a torque of up to 2,000 Nm at 1,100 rpm, first unveiled five years ago during the “FPT Tech Day”. It rolls off the production line at the engine specialist’s factory in Bourbon-Lancy (France) and, by the way, in very large numbers. This is because last year, as many as 10,000 units of what is currently the most powerful CNG engine for the on-road segment were produced here. And demand will remain high, as the Cursor 13 NG engine can be operated with both CNG (Compressed Natural Gas) and LNG (Liquefied Natural Gas) and with biogas without any problems. This makes it ideal for a wide range of applications in logistics and forwarding. However, FPT Industrial also supplies exciting and, thanks to the use of biogas, almost CO2-neutral engine variants for the off-road sector. CNG-Mobility.ch wanted to find out more from Sergio Giordana, Chief Engineer for Alternative Fuels.

Mr Giordana, there is already a tractor with a CNG engine on the market with the 6.75-litre six-cylinder New Holland T6. Now the crawler TK with the F28 engine is about to follow. What are the biggest challenges when developing a CNG engine?

Sergio Giordana, Chief Engineer for Alternative Fuels at FPT Industrial: There are two challenges. The first is to build an engine that performs well compared to a diesel engine. CNG engines are controlled by changing the intake air flow with the throttle valve, while diesel engines are controlled by changing the fuel flow. As a result, CNG engines are inherently less responsive than diesel engines to sudden load changes, as is typical for all-terrain and off-road applications such as tractors. We had to work a lot on the engine control software and the algorithms to make the CNG engine as responsive as possible and to simulate the behaviour of the diesel engine. Another challenge is storing the fuel: this is more of a challenge where the vehicle layout is concerned than engine design, but installing CNG bottles on these vehicles was no easy task.

Does a CNG engine for an off-road vehicle have to meet higher or different requirements than for a passenger car that is primarily driven on well-paved roads?

Yes. Off-road vehicles are not only operated off paved roads, but also in conjunction with various accessories. The way in which the engine has to react to sudden load fluctuations due to the area of application or the requirements of the accessories poses greater challenges for the engine control system than for on-road applications.

The crawler tractor TK with the F28-CNG drive and biogas in the tank now even enables a more climate-friendly wine harvest. Source: FPT Industrial

The crawler tractor TK with the F28-CNG drive and biogas in the tank now even enables a more climate-friendly wine harvest. Source: FPT Industrial

Does FPT Industrial also in principle design its engines for use with biogas?

Our entire range of CNG engines can be operated with biomethane, which is obtained by normal biogas processing, i.e. a purification process.

What are the potential savings in terms of CO2 emissions and other emissions for the CNG powertrain from FPT Industrial?

CNG engines for off-road vehicles reduce CO2 emissions by 10% compared to diesel engines. However, the environmental benefit is even greater if biogas is used instead of CNG. Depending on which starting material is used to produce biogas, the so-called well-to-wheel CO2 emissions can even be negative. As far as other pollutants are concerned, CNG engines with a simple three-way catalytic converter that does not require AdBlue can keep NOx emissions at a very low level. The same low NOx emissions are also a feature of low-output engines of less than 76 hp/56 kW, in which the diesel counterparts do not yet have to be equipped with selective AdBlue catalytic converters and therefore emit much more.

The New Holland T6 with 6.75-litre six-cylinder CNG engine, which has also been available in Switzerland since this year, is another exciting off-road application of an FPT Industrial power unit. Source: FPT Industrial

The New Holland T6 with 6.75-litre six-cylinder CNG engine, which has also been available in Switzerland since this year, is another exciting off-road application of an FPT Industrial power unit. Source: FPT Industrial

With one engine for a tractor and one for a crawler tractor, the CNG range is still a little thin on the ground in the off-road sector. Are further powertrains or performance levels planned or are they already being developed?

We are planning to expand the product range on the basis of the response we receive to the current offering. There is a great deal of interest, and we also have access to our wide range of road engines, which is readily available.

Are there any other areas of application that would be suitable for CNG powertrains from FPT Industrial?

We are considering other applications that are typical for the environment of biofermentation plants. (jas, 5 April 2022)

You might also be interested in

Shell Starship on record hunt