Portal for more climate-friendly mobility

Optimum use of self-produced energy

The innovative farm run by the Wyss family in Ittigen demonstrates how it is possible to produce your own energy and close the cycle using a biogas-powered truck. The versatile operation with its huge in-house biogas plant also supplies fermentation material to other biogas plants in Switzerland in a Scania powered by CNG.

The Wyss family has been producing electricity and heat with its biogas plant since 2005. Source: CNG-Mobility.ch

The Wyss family has been producing electricity and heat with its biogas plant since 2005. Source: CNG-Mobility.ch

Thousands of vehicles use the A1 motorway every day and pass the Wyss family biogas plant, near Grauholz motorway service station. The farm in Ittigen is probably one of the best-known agricultural enterprises in Switzerland and has long established additional sources of income by providing a wide range of services. Agricultural contract work, transportation, block and round baling presses are all part of the farm’s portfolio, along with such activities as municipal assignments and energy production.

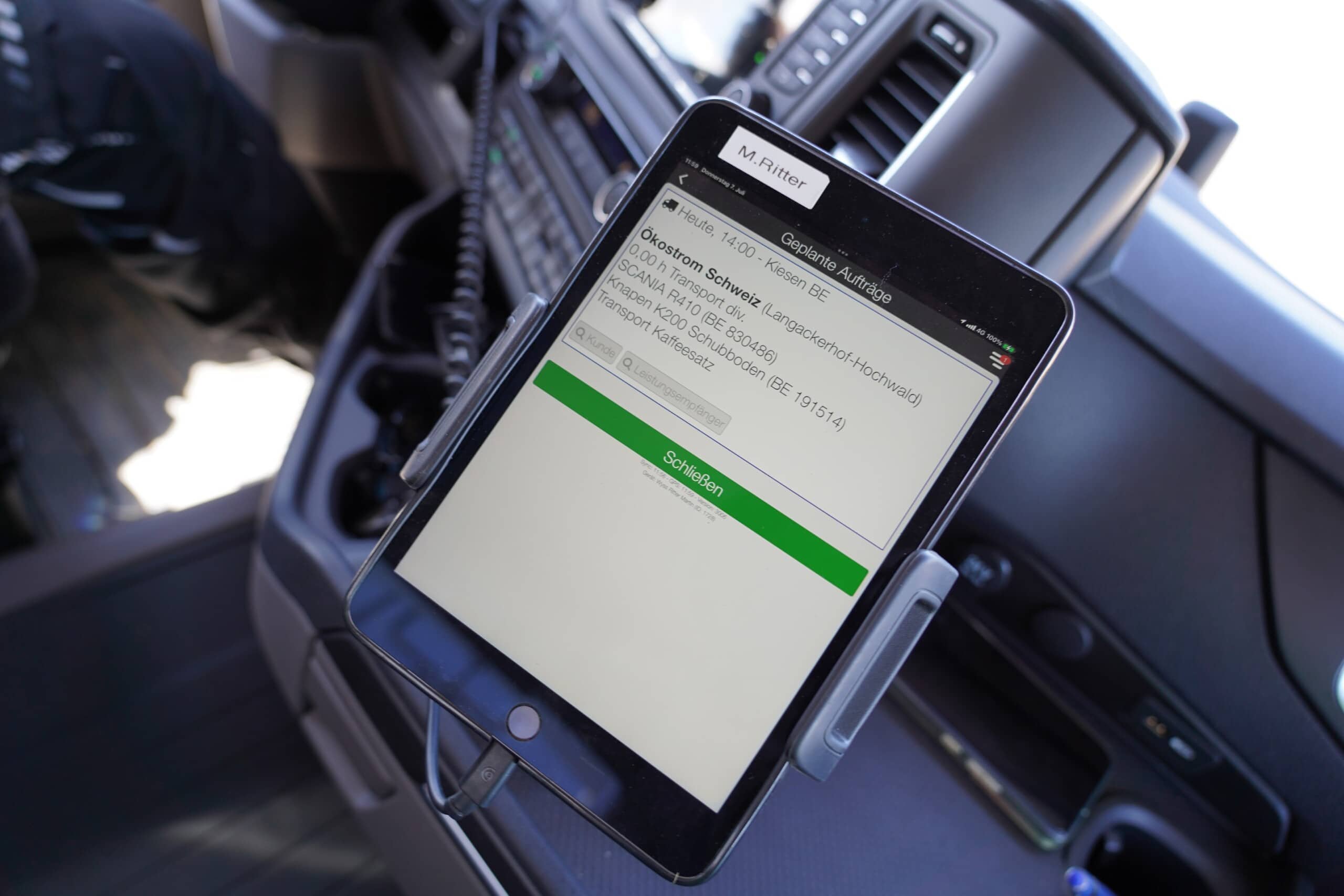

Reto Wyss checks the availability and current location of a machine for a short-term assignment – thanks to advanced digitalisation, this has long been a matter of course at the Ittig company. Source: CNG-Mobility.ch

Reto Wyss checks the availability and current location of a machine for a short-term assignment – thanks to advanced digitalisation, this has long been a matter of course at the Ittig company. Source: CNG-Mobility.ch

The innovative company has more than 55 registered vehicles, including include almost twenty large John Deere tractors, three self-propelled harvesters and a total of eight semi-tractors. It also runs numerous trailers and machines with green number plates. “We do between 900 and 1,700 hours per vehicle per year,” says Reto Wyss. So the despite fuel-saving engines, the fleet has enormous fuel requirements. Wyss gives an example: “14,000 litres of diesel arrived on Monday – and it was all gone by Thursday.”

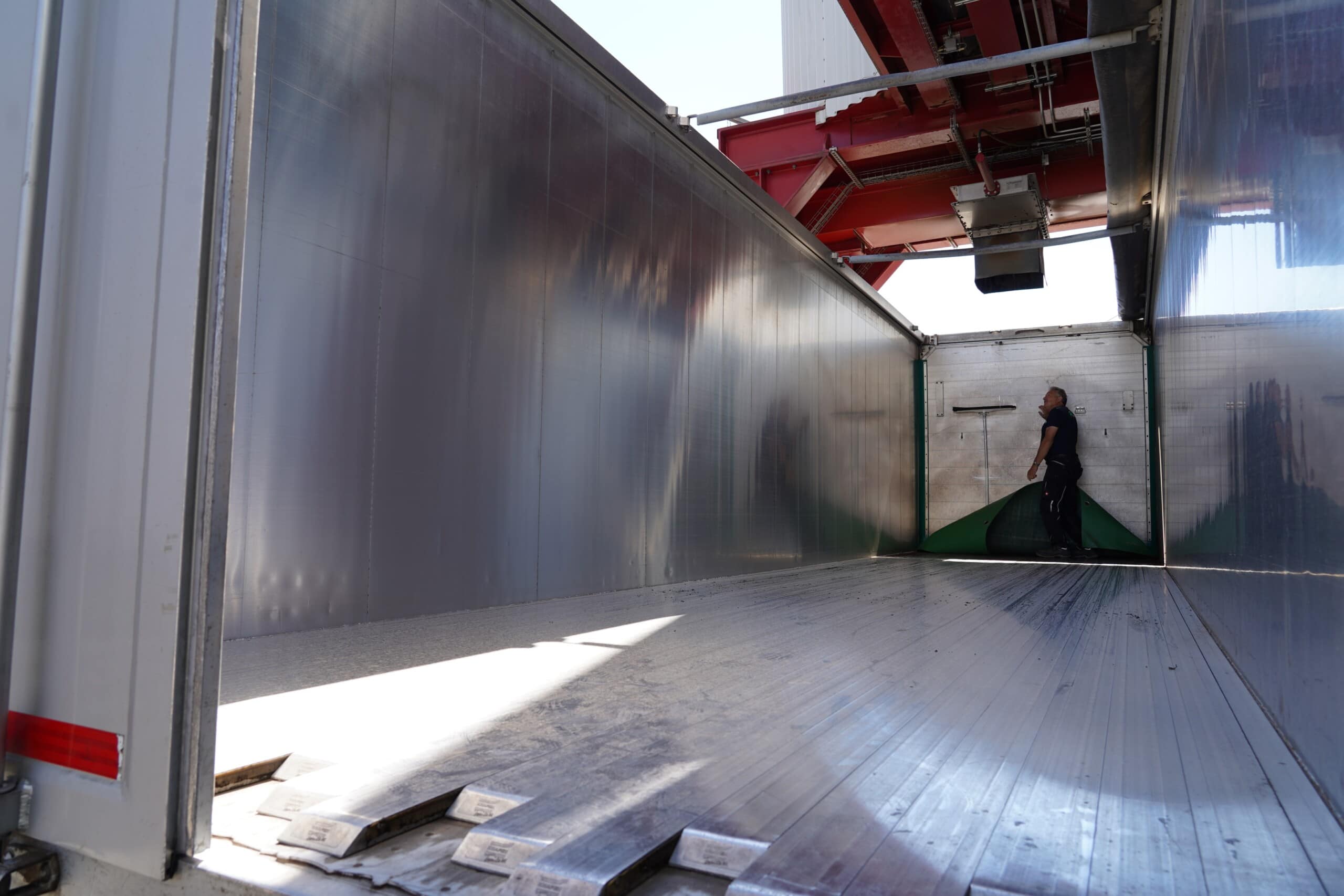

Martin “Tinu” Ritter collects a load of coffee grounds with the CNG Scania at Haco, the specialist for customised food products, in Gümligen. Source: CNG-Mobility.ch

Martin “Tinu” Ritter collects a load of coffee grounds with the CNG Scania at Haco, the specialist for customised food products, in Gümligen. Source: CNG-Mobility.ch

A little over six months ago, a Scania tractor unit with CNG drive arrived at the farm in Bern, with the necessary ground clearance to allow easy manoeuvring on unpaved roads or on construction sites. At the wheel, Martin Ritter is just checking the last details on the narrow tablet in the cockpit. “We’re very digital,” explains the 68-year-old. As a contracting company, Wyss in Ittigen has up to 30 people working for it per day. As such, it’s vital for the vehicle deployment to be well organised, and good drivers and operators are required, too. This is where digitalization is helping, something that senior manager Peter Wyss and his sons Stefan and Reto have done a lot to push ahead with.

The 68-year-old has enjoyed sitting behind the wheel for the Wyss family since his retirement. Source: CNG-Mobility.ch

The 68-year-old has enjoyed sitting behind the wheel for the Wyss family since his retirement. Source: CNG-Mobility.ch

The former head of operations at Kapo Bern, “Tinu” Ritter, has known the Wyss family for a long time and is now happy to help out as a driver. Today, he’s on the road again in the new Scania with CNG drive. “The truck drives very well, but at full load and going uphill to Fribourg or later on in the Jura mountains, you can tell that it has a different torque curve as compared to a diesel,” he says. But first it’s time to visit Haco, the specialist for tailor-made food products, in Gümligen. Around 24 tonnes of coffee grounds are to be loaded up here. “We supply the coffee grounds as fermentation material to various biogas plants in Switzerland on behalf of Oekostrom Schweiz,” says Ritter. Very smart: he uses his biogas-powered truck to deliver the raw material for new biogas on a virtually CO2-neutral basis, thereby reducing waste volumes and closing material cycles.

Coffee grounds are an ideal substrate to be used together with manure and slurry in agricultural biogas plants. Source: CNG-Mobility.ch

Coffee grounds are an ideal substrate to be used together with manure and slurry in agricultural biogas plants. Source: CNG-Mobility.ch

“Fully loaded and running through hilly terrain, you have a range of about 300 kilometres, but you can easily get 350 kilometres without a load,” explains Ritter, skilfully taking the next bend. “I like to refuel in Burgdorf or at the EWB headquarters at Forsthaus. Both filling stations are particularly easy to access with a trailer. And they also have a pump with the larger nozzle that’s suitable for lorries.” Shortly afterwards, the road to Marly is closed due to construction work – no problem for Tinu. He quickly pulls up to the right and gets his bearings on his tablet. “As a driver, you always have to be flexible. I have the standard truck navigation device, too, so we don’t end up on the wrong track on roads that aren’t easy for a lorry.” With some biogas plants that are not so conveniently located, he’s glad the CNG-powered Scania has air suspension: this helps the trailer get a little more ground clearance, he says.

Whether it’s new substrate for a biogas plant or other goods, thanks to CNG propulsion and biogas in the tank, the Scania completes all these transports almost CO2-neutral. Source: CNG-Mobility.ch

Whether it’s new substrate for a biogas plant or other goods, thanks to CNG propulsion and biogas in the tank, the Scania completes all these transports almost CO2-neutral. Source: CNG-Mobility.ch

The journey continues to the biogas plant AgroGaz Haute Sarine SA in Ferpicloz, where the coffee grounds are deposited alongside other substrate. “We don’t just deliver, we also collect fermentation waste – it’s very much in demand at the current very high fertiliser prices,” Ritter reveals. The fermentation manure that is left over at the biogas plants after the fermentation process can be applied to the field as refined farm manure. The good thing here is that, it is easier for plants to absorb and has lower emissions than conventional manure. Martin Ritter enjoys driving his CNG truck, “even though I’m not yet familiar with all the assistance systems and refined details the vehicle has to offer. The trips allow me to get to know Switzerland even better and drive through areas I’ve never been to before.” And thanks to biogas, all these transportation trips are almost CO2-neutral – that’s how the circular economy works! (jas, 2 August 2022)

You might also be interested in

Shell Starship on record hunt