Portal for more climate-friendly mobility

Hidden champion of the energy industry

Apex has been an established player in the Swiss energy industry for 20 years: Whether plant construction or gas station maintenance, the people from Solothurn know their stuff. To mark the anniversary, Apex owner Ueli Oester invited guests to an exchange of knowledge and an open day.

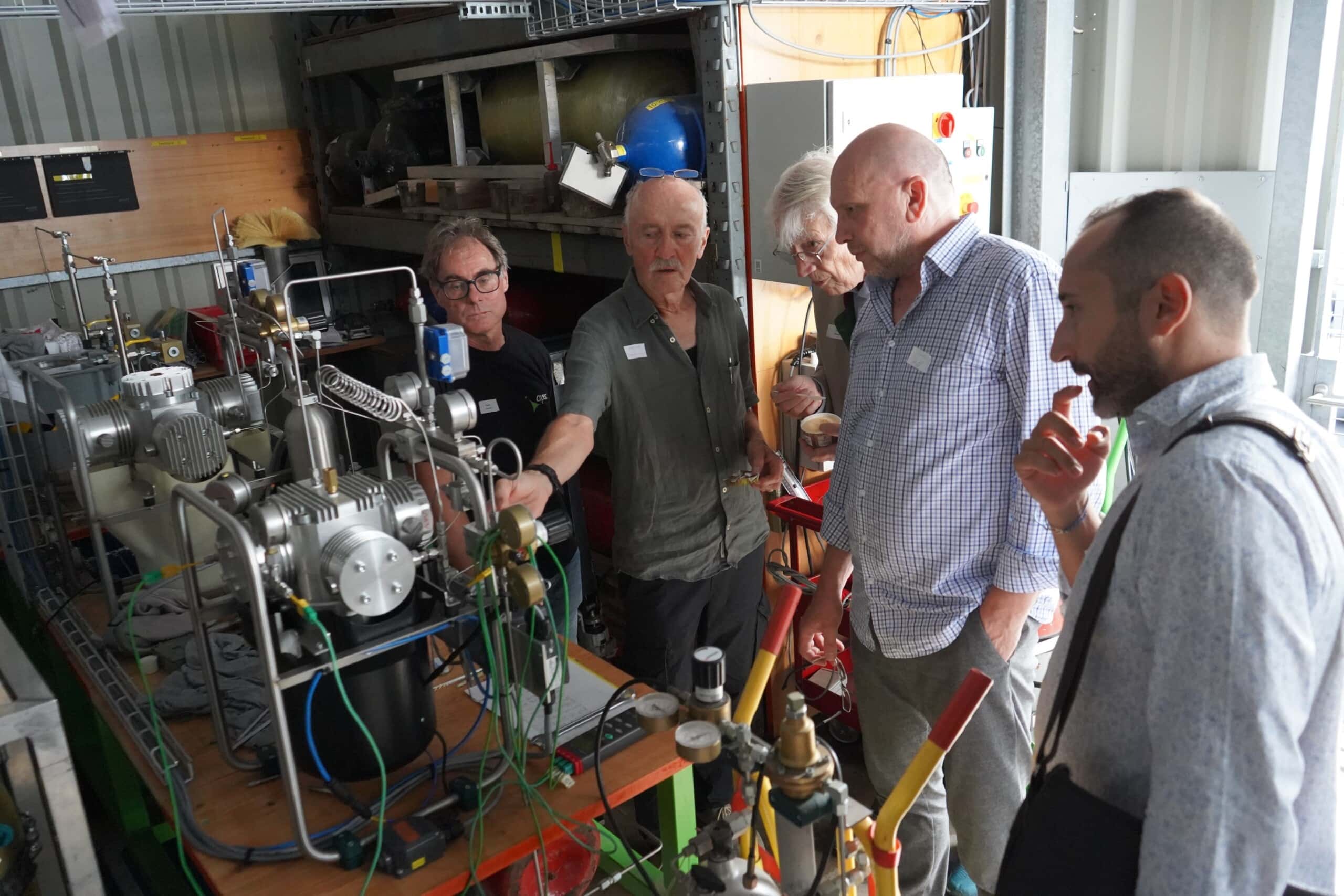

Many guests took advantage of Apex’s 20th anniversary to take a closer look at the exhibits on display. Source: CNG-Mobility.ch

Many guests took advantage of Apex’s 20th anniversary to take a closer look at the exhibits on display. Source: CNG-Mobility.ch

Quite inconspicuously hidden in the industrial quarter of Däniken in the canton of Solothurn is a Swiss company that is indispensable when it comes to renewable gases, gas filling station construction and maintenance, medium and high-pressure compressors, industrial gases and storage cylinder disposal: Apex AG. Together with his team, founder and owner Ueli Oester forms a competence centre for all these topics – and has done so for 20 years.

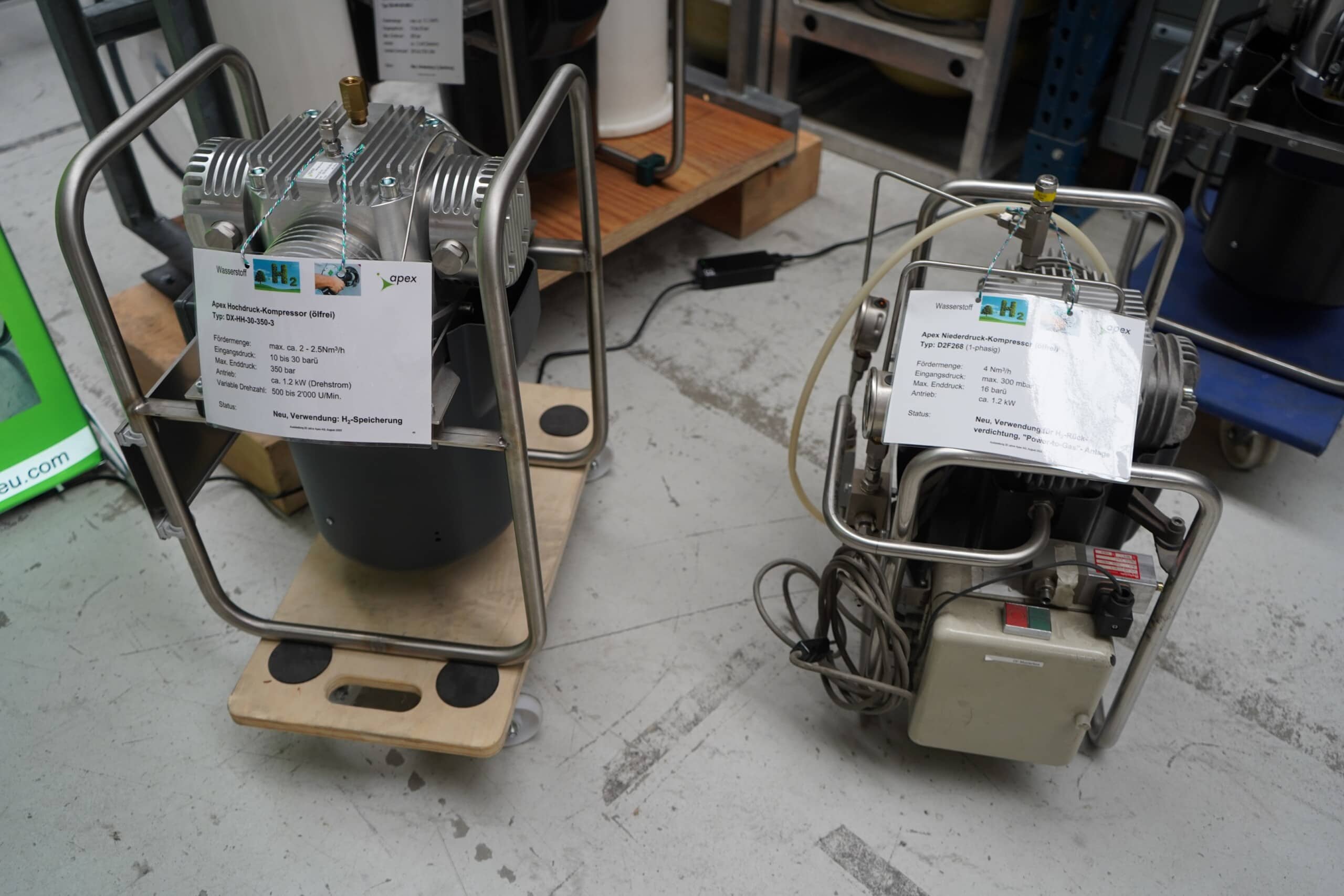

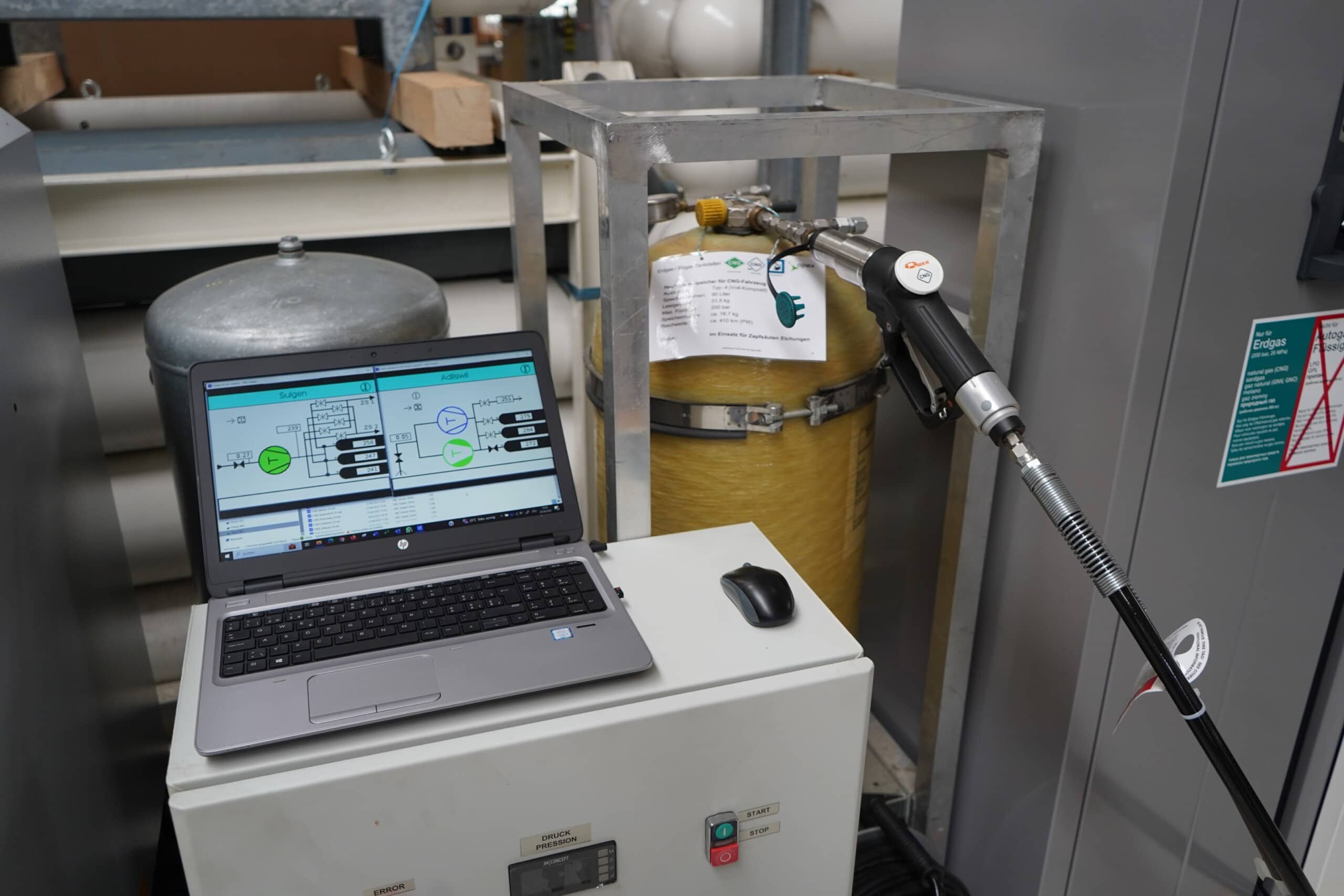

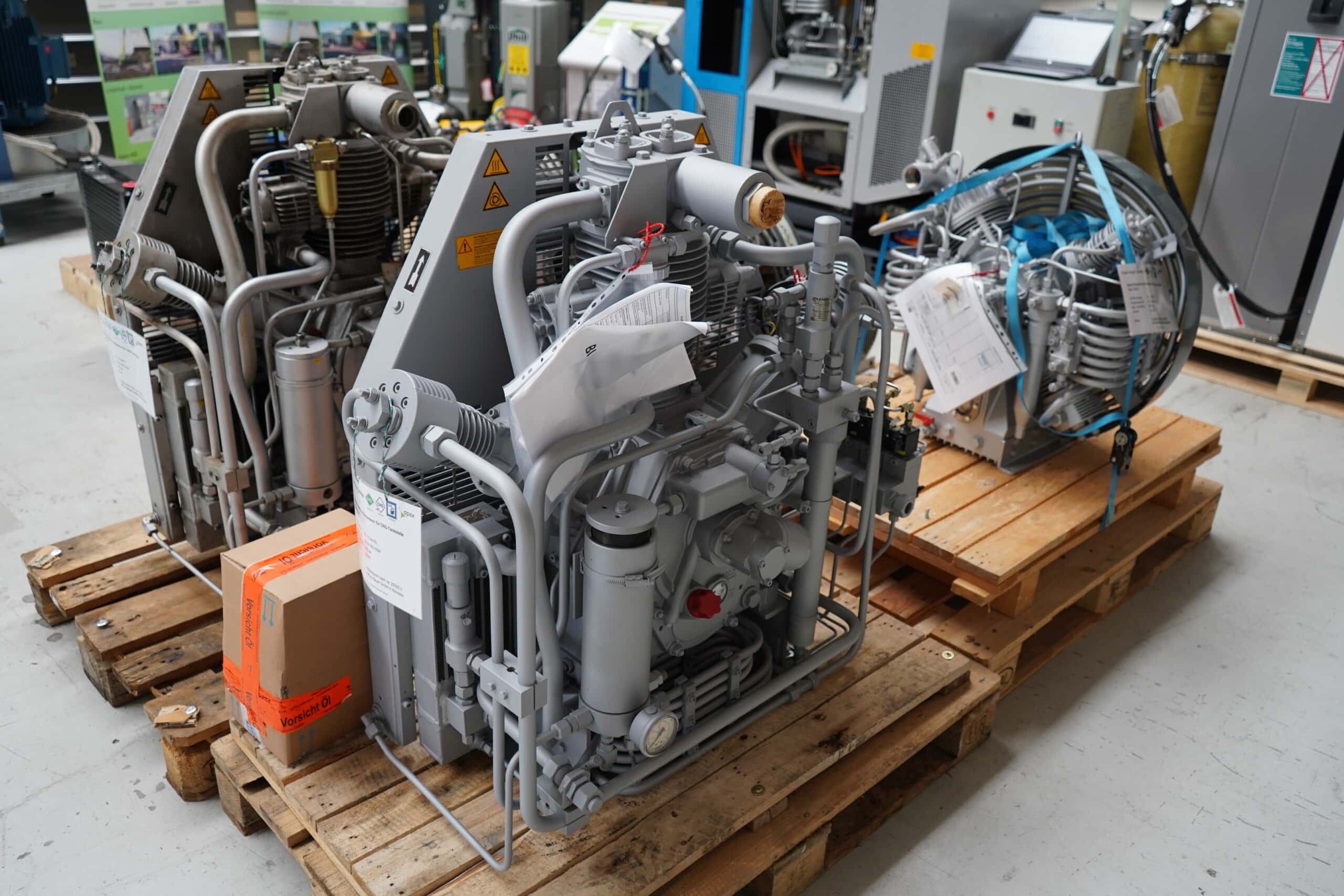

Compressors, superchargers and storage tanks – Apex in Däniken, Solothurn, has been taking care of them for years with a great deal of know-how. Source: CNG-Mobility.ch

Compressors, superchargers and storage tanks – Apex in Däniken, Solothurn, has been taking care of them for years with a great deal of know-how. Source: CNG-Mobility.ch

“I founded Apex in 2002 as a sole proprietorship, because then you can raid your pension fund and start your business that way,” recalls owner Oester. “After a year, I then founded Apex AG on 14 February 2003 and started, among other things, with the maintenance, repair and installation of CNG and biogas filling stations.” Today, the company looks after more than 50 per cent of Switzerland’s gas filling stations and operates some itself. “But our focus has changed somewhat,” admits Oester on the occasion of the big 20th anniversary, “we are now concentrating more on biogas and hydrogen. And we are also working on power-to-X projects with the University of Applied Sciences of Eastern Switzerland.”

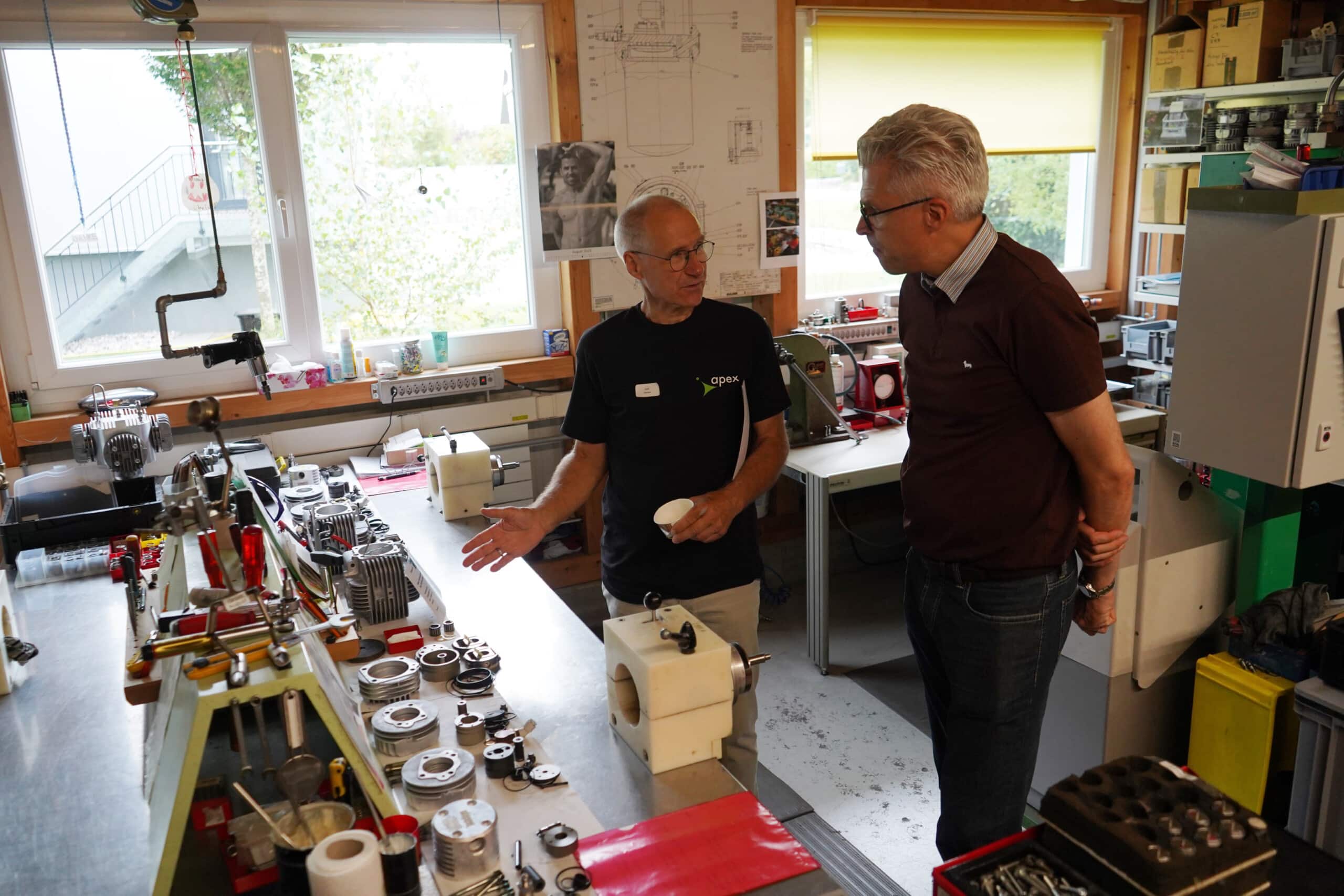

Apex owner Ueli Oester (left) in conversation with Markus Friedl, professor of thermodynamics and fluid dynamics at the University of Applied Sciences of Eastern Switzerland. Source: CNG-Mobility.ch

Apex owner Ueli Oester (left) in conversation with Markus Friedl, professor of thermodynamics and fluid dynamics at the University of Applied Sciences of Eastern Switzerland. Source: CNG-Mobility.ch

No wonder, therefore, that on the occasion of the company’s anniversary, for example, the professor for thermo- and fluid dynamics and Markus Friedl, institute director of the University of Applied Sciences of Eastern Switzerland (OST), also dropped by. Heinz Bauer, senior director of the renowned Bauer Group, a high-pressure and screw compressor specialist with 22 subsidiaries and over 350 sales partners worldwide, did not miss the Apex anniversary either. He not only listened to the workshops, but also took a close look at the various exhibits on the company premises.

Alexander Diethelm of Mems AG (left) explains details of the latest Mems measuring devices to Heinz Bauer of the Bauer Group. Source: CNG-Mobility.ch

Alexander Diethelm of Mems AG (left) explains details of the latest Mems measuring devices to Heinz Bauer of the Bauer Group. Source: CNG-Mobility.ch

The 83-year-old also had the latest gadgets explained to him. For example, an ATEX-certified measuring device from Mems, which can determine various gas quality factors such as calorific value, density, compressibility or even hydrogen content and which Apex likes to use in biogas plant construction. For the Apex anniversary, owner Oester, managing director Bora Culhaoglu and their team organised the whole range of CNG vehicles, from the impressive Iveco truck to the practical Piaggio Porter to various CNG cars and, of course, one of the first New Holland tractors powered by CNG in Switzerland. “It’s actually quite simple: without filling stations there are no cars and, conversely, without vehicles there are no filling stations,” muses Oester. That’s why Apex has always been in the lead when it came to bringing new technologies to market or optimising them.

From the CNG-powered truck to the CNG tractor to the practical all-rounder Piaggio Porter CNG-powered vehicle, they all depend on a CNG filling station. Source: CNG-Mobility.ch

From the CNG-powered truck to the CNG tractor to the practical all-rounder Piaggio Porter CNG-powered vehicle, they all depend on a CNG filling station. Source: CNG-Mobility.ch

This is the case with the Blue Bonsai, a newly developed biogas upgrading plant with integrated biogas filling station, which went into operation in summer 2016 and already achieved almost 2000 operating hours in its first year of operation. Design, cost and operational analysis still showed optimisation possibilities, so the plant was rebuilt and the upgrading capacity doubled. Ueli Oester and his team also managed to halve the specific investment and operating costs: Just one example of the Apex team’s innovative power and striving for better, clever solutions. If something is not yet available on the market, the Däniken team sometimes develops it themselves, such as the software for the biogas selection button at the Swiss petrol pumps.

Apex was also innovative in gas processing and further developed the membrane for gas separation. Source: CNG-Mobility.ch

Apex was also innovative in gas processing and further developed the membrane for gas separation. Source: CNG-Mobility.ch

“Our know-how is not only needed for the construction of pipe storage tanks or the use of compressors, but also for the maintenance of the plants and filling stations, where a large number of services are required, such as calibration, rapid replacement of filling couplings or even the replacement of the molecular sieve,” explains Oester. “We offer these at Apex, as well as training courses on these topics.” Time and again, his company has also been able to further develop products together with innovative customers. For example, with Reto Grossenbacher from Reidermoos LU, a small-scale biogas upgrading plant for 20 cubimetres/hour was developed. And soon Energiewirt GmbH will start operating a biogas plant that feeds biomethane into the local grid thanks to an Apex upgrading plant in a compact 20-foot container.

During the anniversary event, exciting workshops provided insight into the business fields worked on by Apex. Source: CNG-Mobility.ch

During the anniversary event, exciting workshops provided insight into the business fields worked on by Apex. Source: CNG-Mobility.ch

“Our vision is to close supply gaps with small, independent biogas plants and tank facilities at innovative farms as well as sewage treatment plants – this potential is still largely unused in Switzerland and, unfortunately, has also been too little recognised by politicians so far,” says the Apex owner. But Ueli Oester and his company would not be among the hidden champions of the Swiss energy industry if he did not look beyond CNG and biogas. That is why a Toyota Mirai with fuel cell drive is in the parade of vehicles at the anniversary, and Jörg Merz, Managing Director of AGVS Central Switzerland and hydrogen expert, explains the current state of the art in the H2 sector to those present. In addition to cutaway models of an H2 storage bottle and Hyundai H2 engines, he also shows how hydrogen burns – an aha experience for many, as the flame is only visible on the infrared camera and does not emit any heat.

Jörg Merz, Managing Director of AGVS Central Switzerland, uses cutaway models to illustrate the challenges of hydrogen propulsion. Source: CNG-Mobility.ch

Jörg Merz, Managing Director of AGVS Central Switzerland, uses cutaway models to illustrate the challenges of hydrogen propulsion. Source: CNG-Mobility.ch

“We also have to gain solid experience with H2 and develop the technology further,” explains Oester. That is why his company is also working on its own H2 compressor. “It has already reached 500 bar, but is not yet where you want to be with the flow rate,” he says. “Moreover, you don’t just have to make sure that something works well, but that the maintenance concept is also right and that you can easily replace a compressor head, for example.” After 20 years at the helm of Apex, Ueli Oester has also replaced himself. Since the beginning of 2023, the mechanical engineer and plant construction specialist Bora Culhaoglu has been responsible for the business. And with his typical, mischievous smile, Oester concludes: “If we had remained a pure CNG service company, there would have been no need for a new boss. If we didn’t invest in hydrogen and the future, Apex would have retired with me.” (jas, 5 September 2023)

Apex managing director Bora Culhaoglu (left) and Apex owner Ueli Oester talking to a customer. Source: CNG-Mobility.ch

Apex managing director Bora Culhaoglu (left) and Apex owner Ueli Oester talking to a customer. Source: CNG-Mobility.ch

More impressions of the 20-year anniversary

You might also be interested in

Shell Starship on record hunt